Sustainable Aviation Fuel (SAF)

We are working on projects in Norway and Sweden to convert non-recyclable waste into SAF. Our current focus is on outlining the technical setup, economic viability, and environmental impact of the SAF production facilities.

How will we do it?

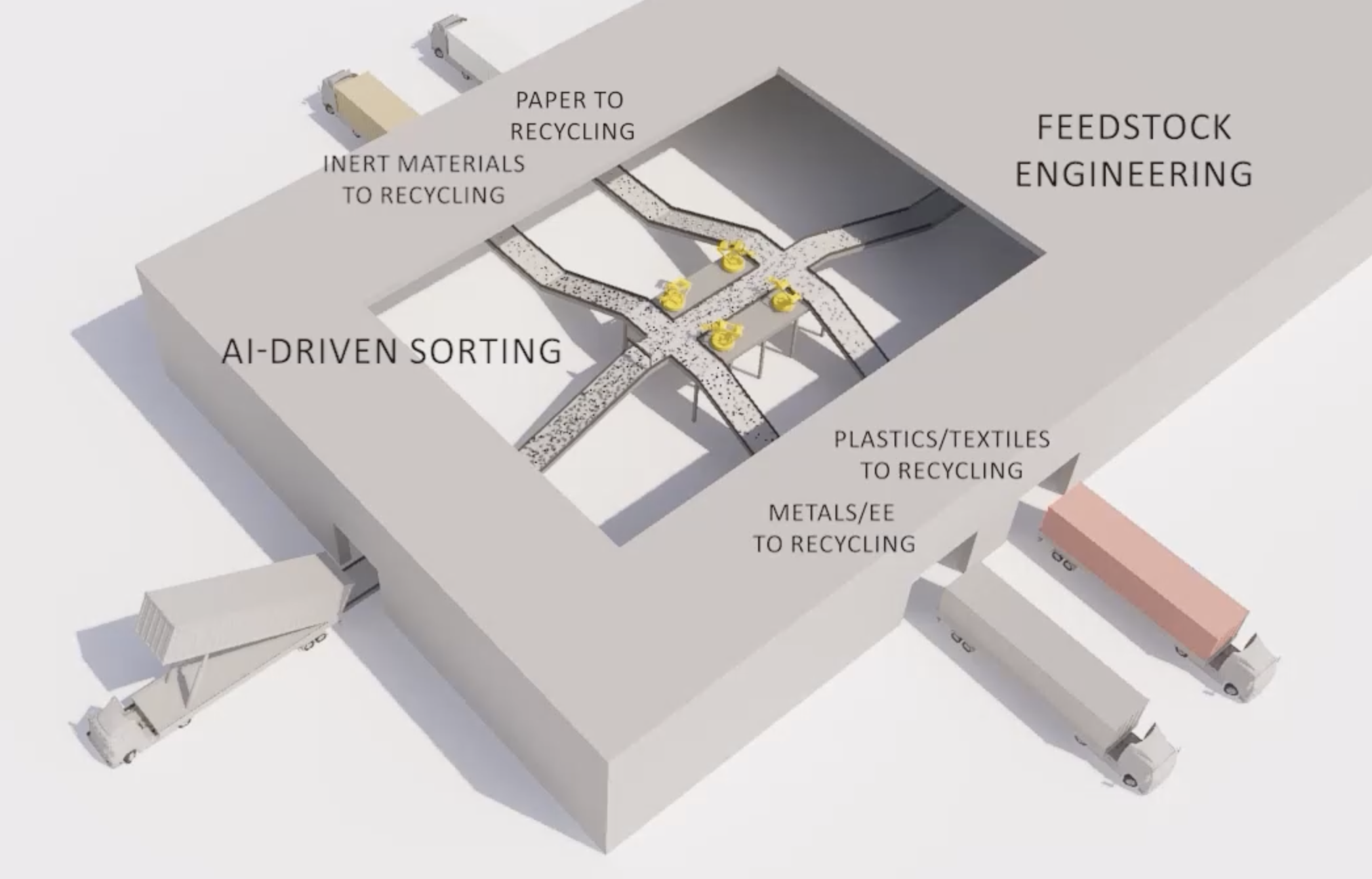

SAF production from waste materials represents a transformative solution for addressing two critical challenges: waste management and sustainable aviation fuel. The solution both diverts waste from landfills and incineration and produces a valuable energy carrier. Non-recyclable waste, including residual waste and industrial residues, can be converted into SAF through a process called gasification. The process treats waste materials at high temperatures (>1200°C) without combustion, breaking them down into a synthetic gas (syngas). The syngas is then synthesized into longer chains of hydrocarbons in order to produce SAF.

Why?

SAF offers a sustainable alternative to conventional fossil-derived aviation fuels, as it significantly reduces CO2 emissions. It does not require changes to existing aviation infrastructure and fulfills the same technical and safety standards as traditional aviation fuel. The EU has set ambitious climate targets for 2030 and 2050, and increasing the use of SAF is one of the key tools for decarbonizing aviation. By 2035, EU airports and fuel suppliers are obliged to ensure that 20% of aviation fuel is green, with the requirement increasing to 70% in 2050.

Want to know more?

Adis Cengic

Chief Business Development

Adis has more than 15 years of experience from industry, including leadership roles at NG Nordic, Avery Dennison, and Norsk Hydro. As a Production Director at NG Nordic, he built one of the most sophisticated paper sorting machines in Northern Europe. Adis holds a BSc in Computer Science from the University of South Wales and a BSc in Electronics from Bergen Tekniske Fagskole.